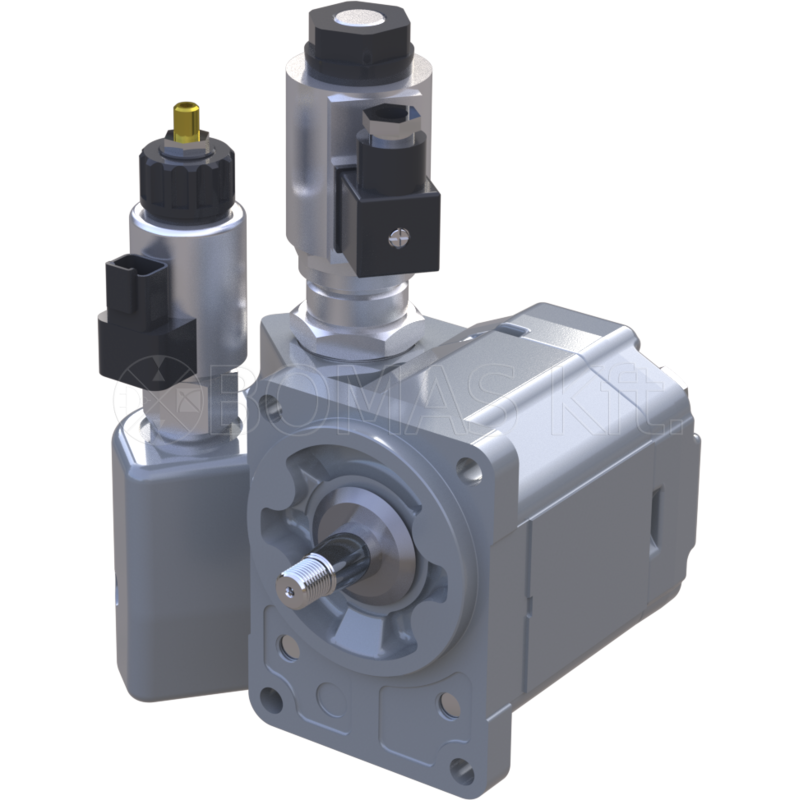

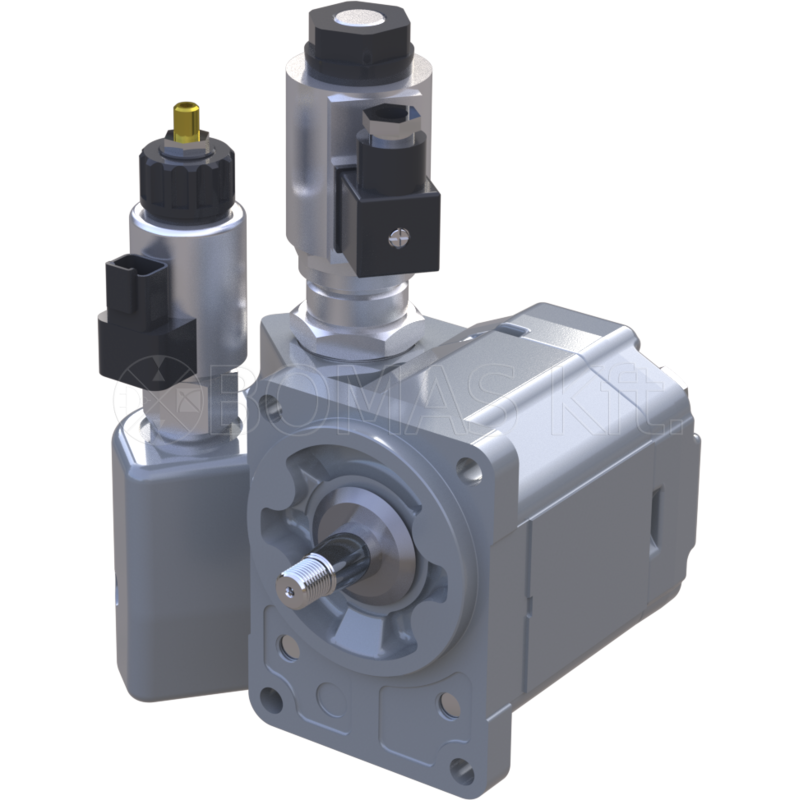

Features and Benefits

• Two groups of frame size (Group 2 and 3)

• Steel and cast iron rear covers for 250 bar [3626 psi] continuous performance and 270 bar [3916 psi] peak pressure for all port configurations

• Displacement from 8 to 44 cm3/rev [from 0.51 to 2.69 in3/rev]

• Maximum speed 3500 min-1 (rpm) for Group 2 and 2500 min-1 (rpm) for Group 3

• Extreme temperature seals for continuous operation from –20°C [–4°F] up to 95°C [203°F], for today's more demanding applications.

• Two electro-hydraulic proportional valve options: PRV for standard fan speed modulation and optional flat curve valves for such applications as fan motors in series.

• DEUTSCH electrical connectors as standard to withstand dust and debris in the environment.

• 12 VDC and 24 VDC coils.

• Fail safe function - full fan speed if electrical signal fails.

• Pressure settings factory pre-set for individual system performance.

• High efficiency gear motors to reduce system losses and retain useful hydraulic power work functions

• Outrigger bearings available for all 3 models to provide increased bearing capacity and therefore more durability or extended life in applications such as slewing, tracked machines, vibe and shock load applications that possess gyroscopic and impact loads or heavy steal fan blades

• Shaft seal dust protector standard on all models for extended seal life in fan drive applications

• 2 Anti-Cavitation High Pressure Shock Valves, to clip pressure spikes in both directions of motor rotation, while reversing, where the competition uses only 1

• Integrated Reversing Directional Control Valves with open spool transitions to reduce system pressure spikes

• High performance valves and the use of steel / cast iron allows for full system pressure capability without de-rating the SGM product during reversing or proportional control

• Integrated valves packages and factory sealed outrigger bearings with high speed capability to preserve engine space

• PLUS+1® Compliant electronic interface allows for integration with PLUS+1® micro-controllers and other compliant products including sensors and graphical displays

Download Technical Information

Download Technical Information (Ultra-short fan drive motor)