Our brand independent repair workshop is operating in Hajduszoboszlo, Hungary since year 2000. We are specialised in the repair of hydraulic pumps, motors, steering units, valves, cylinders and other main system components. In the previous decades thousands of units were handled by our company. Our strong, wide supplier base allows us to handle many hydraulic products from all over the world. We solve our Customer's needs either with our repair services, or parts sale, and even the trade of genuine or OEM-made complete units if needed. Sometimes we also have the ability to offer alternative products that match the original as close as possible.

Jump to the gallery.How our services work:

- At the time of the initial contact we ask for all data the Customer can provide. A photo of the identification data plate on the unit, as well as a photo of the machine data plate, or a hydraulic schematic drawing from the documentation can contain valuable data that makes our background work more efficient and quicker. These information may also help us in understanding the structure of the whole system, identifying additional dangers and other faulty units in it.

- Units for repair can be registered and left in our workshop in our opening times (workdays 8:00-16:00), even without appointment.

(Visiting us at a different time or bringing urgent jobs to us always have to be prearranged. These always depend on availability and our capacity.)

- If our Customer would like us to solve the transport of the broken units from their facility, we can arrange shipment using one of our delivery partners. This delivery is on a very fair price and to be invoiced later, no pre-payment is needed! Please ask in e-mail or on the phone!

- Please take care of the following when you send a hydraulic unit by post or a delivery company: All oil must be removed from the inside of the units. Wrap the units and parts properly in plastic bags, if needed, include oil-soaking material, like textile or paper with the units. Oil leaking out of a unit can contaminate other packages. In that case, all costs and responsibilities are always on the Sender!

- When the units arrive for repair we immediatley register them and the contact data of our Customer. These information go straight into our system with "project numbers" which we use to track our work. We use separate boxes for these project numbers and mark them each, thus reducing the possibility of parts loss and mixing with other projects.

- We try to disassemble the units and evaluate the damaged parts as fast as possible. This way we can produce the quotation for our Customer in a quick way so they can decide on the project.

- We always prefer the use of OEM parts (coming from the original manufacturer of the hydraulic unit). Of course, in our suppliers' repertoire we also find good quality aftermarket parts too if strongly needed. In our quotation we always list the parts needed and mark the quality of the parts (genuine/OEM or aftermarket) to be used by us.

- Only after an agreement on our quotation can we start the warehouse picking and ordering any missing parts. If can not agree on any options, the Customer has to pay for the work previously done by us and the delivery costs, before taking the unit away from us.

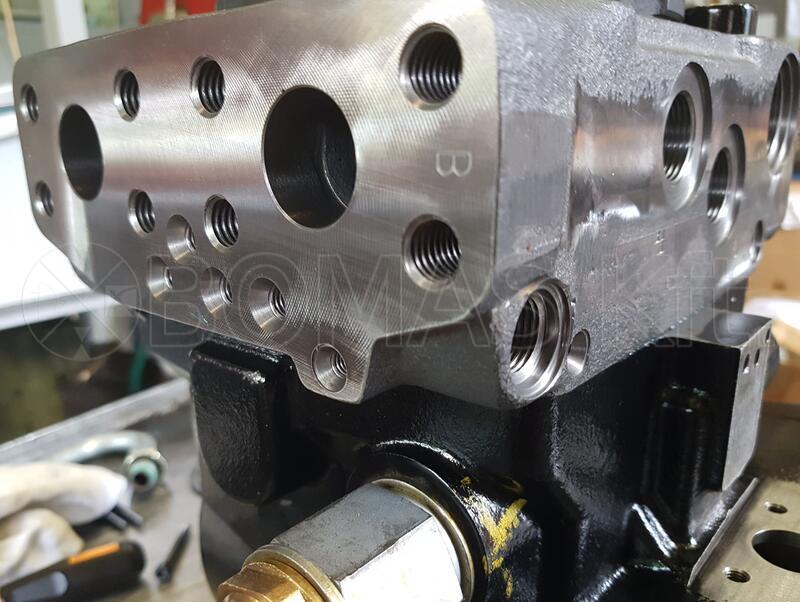

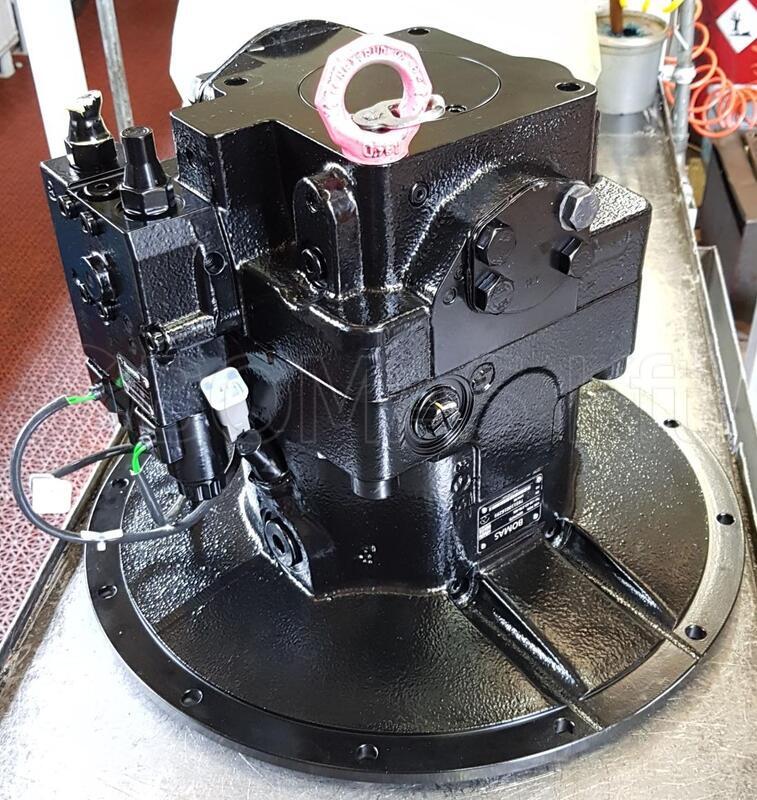

- Before assembly, we thoroughly clean all old and new parts alike and assemble the unit in a clean environment.

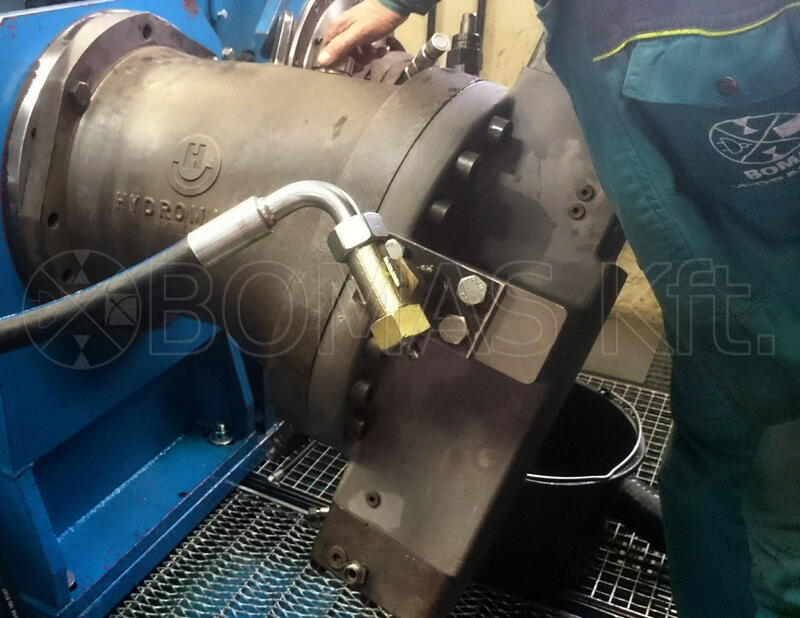

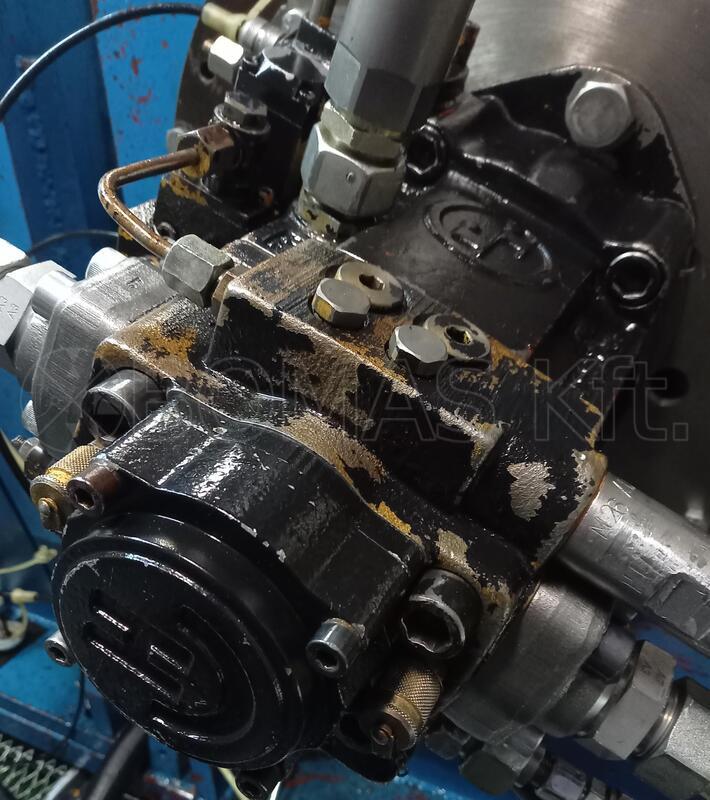

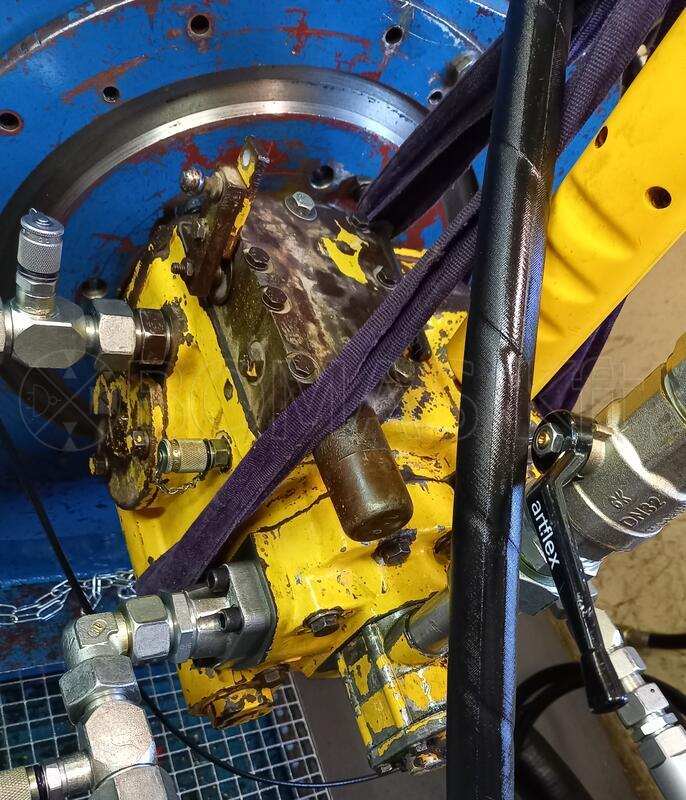

- After assembly, all repaired units go through testing on one of our test benches. Our test capabilities range from the smallest steering orbits and valves to the largest pumps and orbital motors. Our measurements are done by accurate, digital devices. Flow measurement up to 600 liter/minutes, pressure measurements up to 600 bar are possible at us with great accuracy. Parameter settings are done using available data from our background or the data provided by our Customer.

- After the test we notify the Customer and prepare the units ready for shipment. Customer gets basic installation info, which can be used by qualified technicians to install and start-up the units. We offer warranty on our repairs - conditions apply and are detailed in each quotation.

A few reference projects we have finished in the past years:

Hydromatic A7V1000 pump

Industrial press

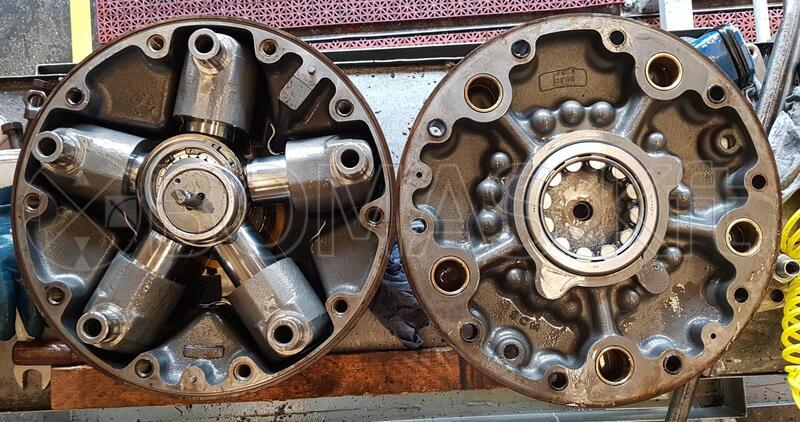

Danfoss orbital hydromotors

Types OMS, OMT, OMV, TMT etc.

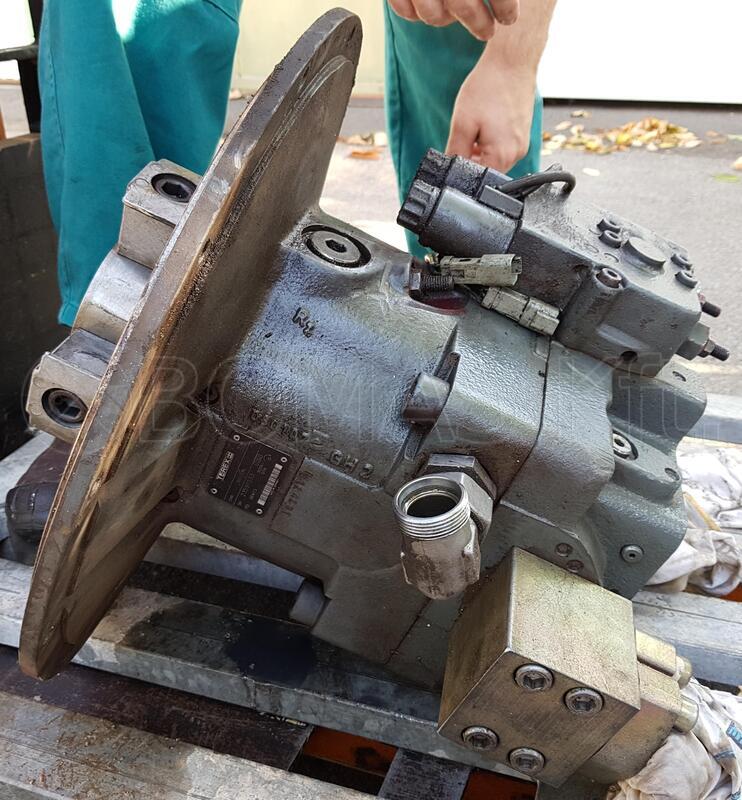

Rexroth A4VG71... pump + A6VM107... hydraulic motor

Merlo telehandler

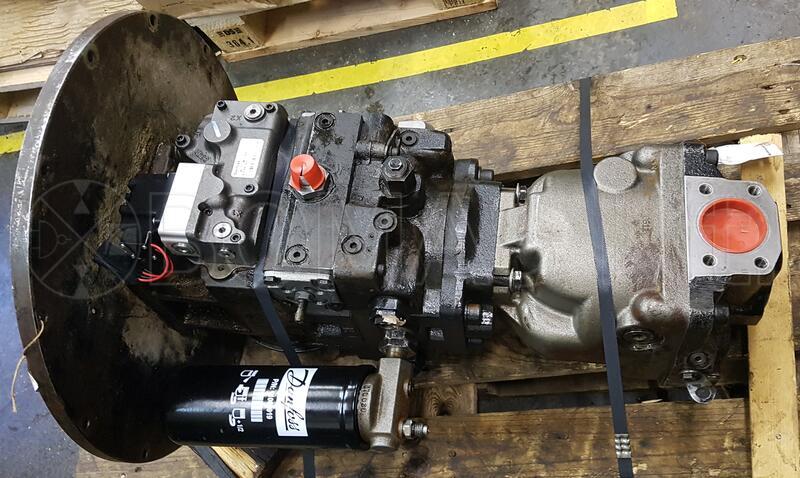

Sauer Danfoss 90R075.. pump + Sauer Danfoss 51V110 hydraulic motor

Merlo telehandler

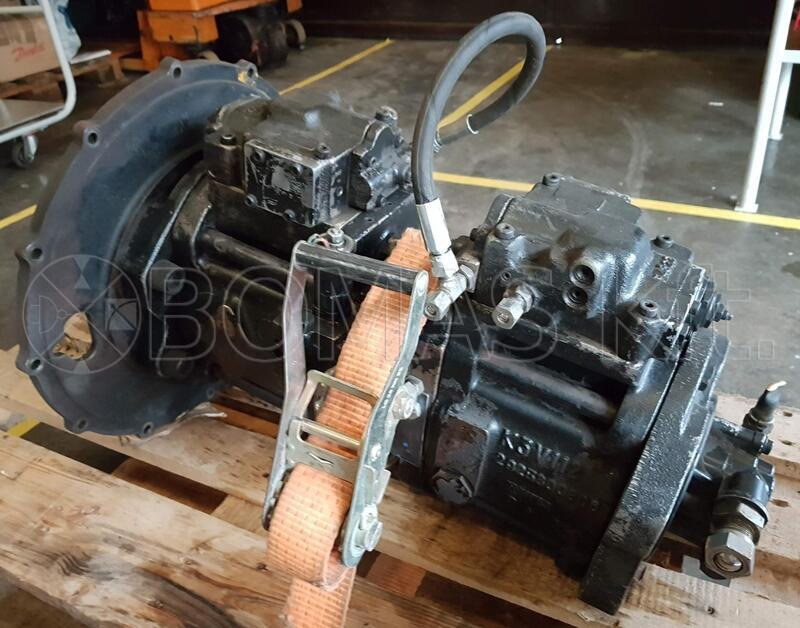

John Deere - Rexroth pump

Agricultural tractor

Linde HPR pump and HMR hydraulic motor

Volvo wheeled excavator

Jahns flow divider

Industrial press

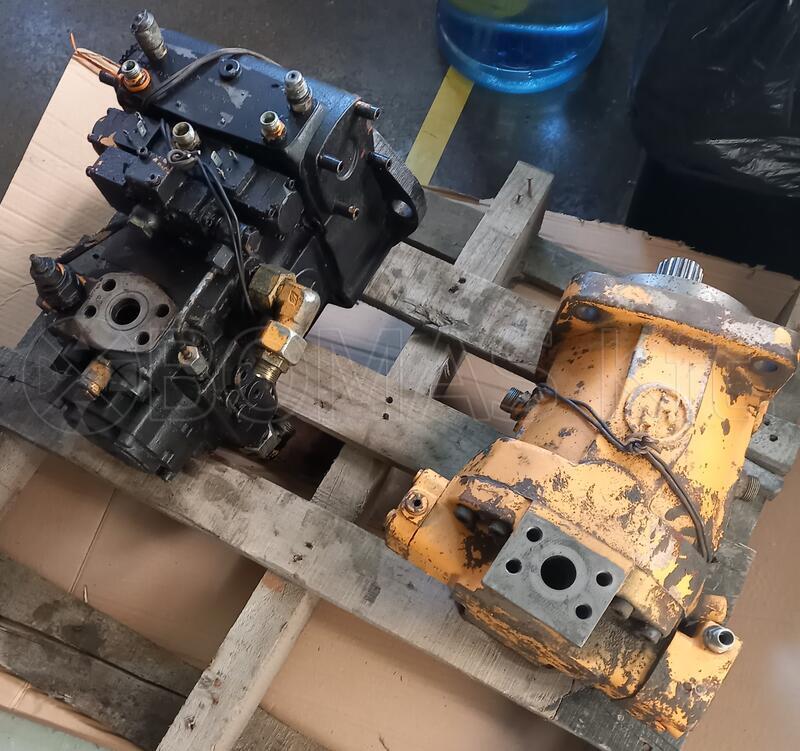

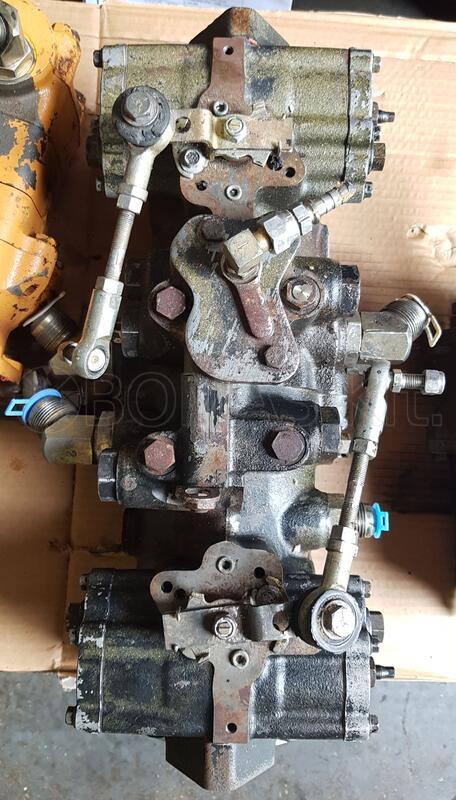

Tandem pump

Bobcat skid-steer loader

Sauer Danfoss 90R130 and IRR130 pumps, 51V250 hydromotor

Fintec / Sandvik crusher

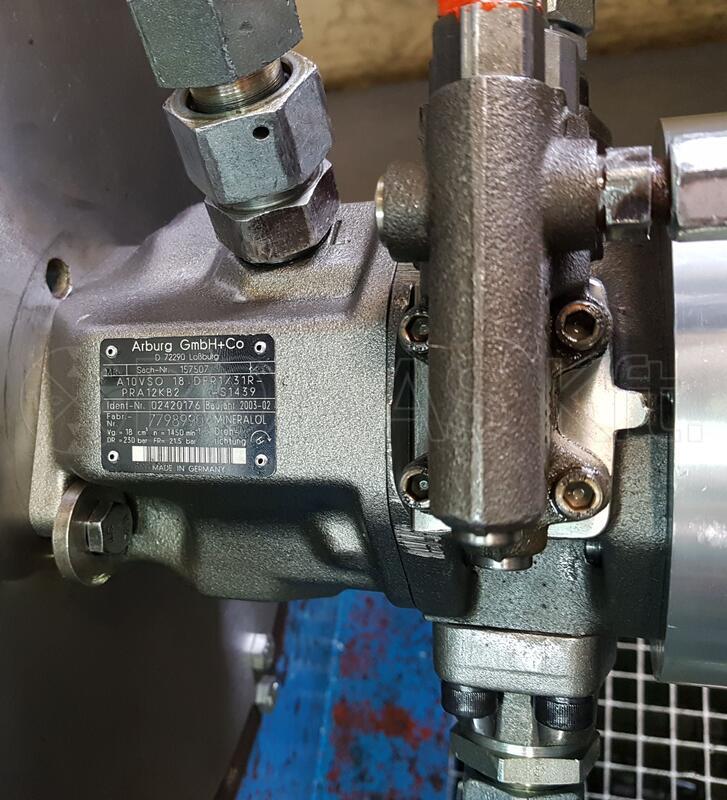

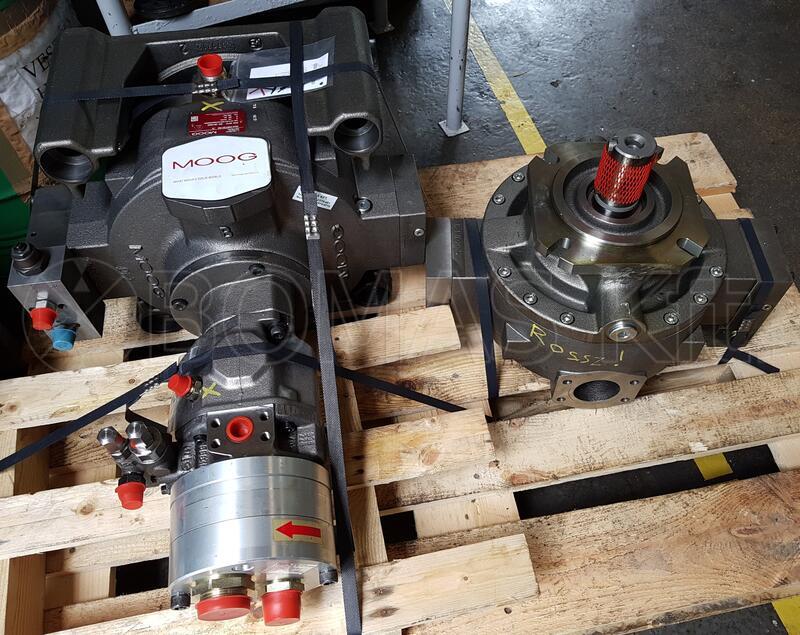

MOOG radial piston pump + AKP18 / A10VSO18 axial piston pump

Arburg injection molding machine

Sauer Siro rotating plunger pumps

Injection molding machines

Sauer Sundstrand / Danfoss 90L180, 90L100, 90R100, MPT046 pumps

Railway construction machinery

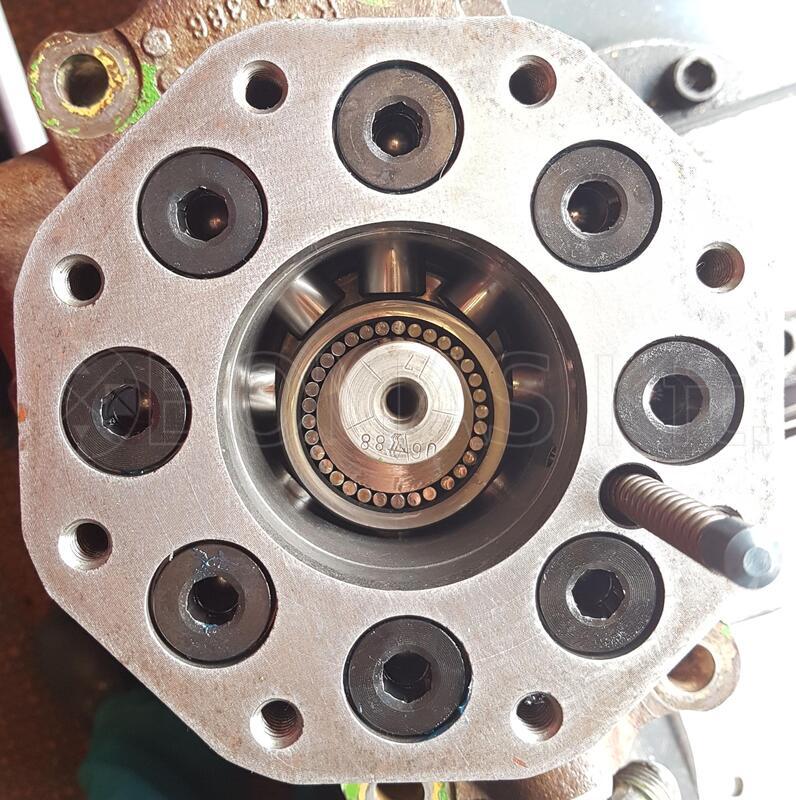

Poclain radial piston hydromotors

Self-propelled sprayers (Hardi, Berthoud, etc.)

Liebherr LPVD pump

Liebherr mobile crane

Danfoss H1P100 pump, TMT FLV motors, SNP gear pump

Novotny forestry forwarder

Danfoss H1T tandem pump, H1B motors

Ponsse forestry forwarder

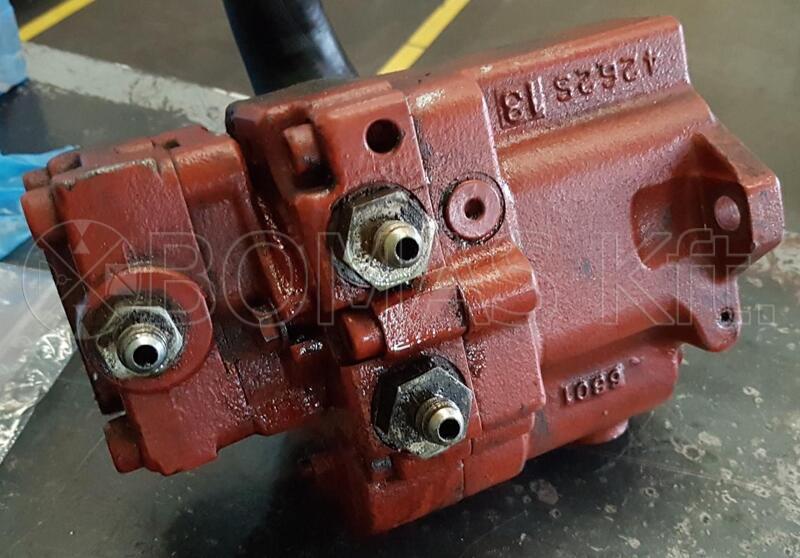

Radial piston pump

John Deere agricultural tractor

Kawasaki KPM type K3V and type K5V tandem axial piston pumps

Tracked excavators

Hydromotor final drives

Tracked excavators

Hitachi twin pumps

Hitachi ZAXIS tracked excavators

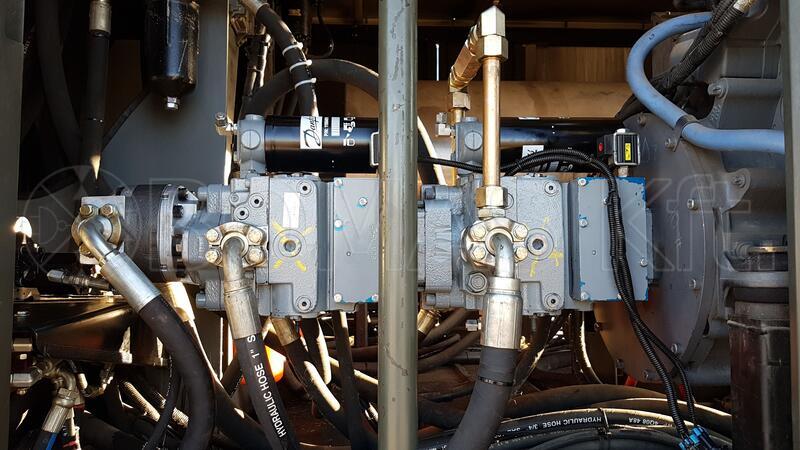

Propel system, 2x Danfoss 90R055 pumps + 4x Danfoss 90M042 motors

Bitelli asphalt layer

A10VSO100 pump

Industrial power pack

Propel system, Danfoss 90R130 + Danfoss 51V160

Claas harvester

Danfoss 90L130 pump

Industrial application

Hydromatik A4V90 A6VM107 hydromotor

Liebherr wheel loader

Nachi PVD pumps

Mini excavators (JCB, Bobcat, etc.)

Stacked directional control valve

Railway construction machine

Danfoss PVG32 valves

A2FM... hydromotors

Danfoss OSPB and OSPC steering units

Self propelled machines, tractors

KPM Staffa hydromotor

Winch application

Sauer SPV pump

Wheel loader

Danfoss MPT pump + Danfoss OMT FLV motors

CASE skid steer loader

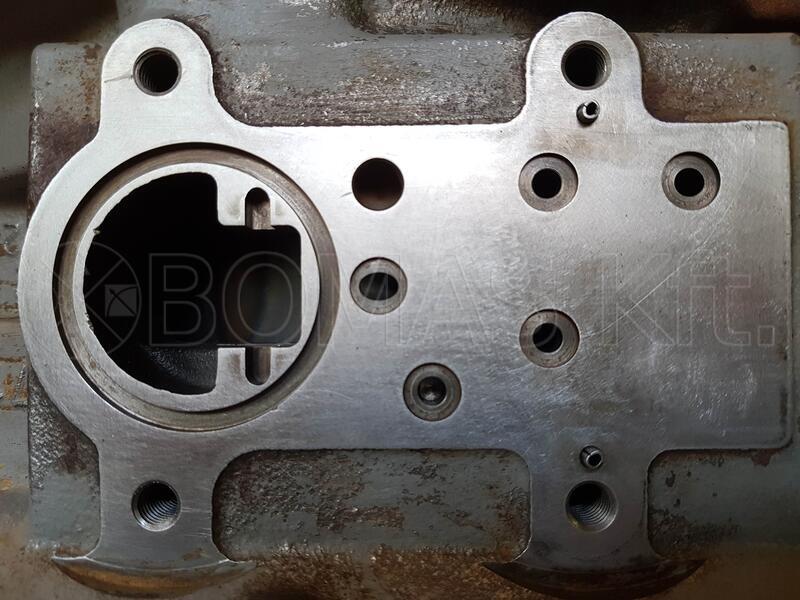

SAI radial piston pump

Railway construction machine

Rexroth A11VO pump

TEREX mobile crane

Hydraulic swivel

Hansa excavator

A11VO130 main + A4VG40 swing pumps

CAT M315 wheeled excavator

Kawasaki KPM K3VL140 pump

Industrial power pack

Sauer Sundstrand 2x 90L100 axial piston pumps, CPB gear pump, MMF025 axial piston motor

Airport de-icer

Tuff Torq compact hydrostatic drive

John Deere mower

*The machinery brands noted in the above text are mentioned only as reference.